As the manufacturing industry continues to evolve at a rapid pace, companies that prioritize innovation and sustainability are leading the way into a new era. Among these trailblazers, Repmold has emerged as a pivotal player, transforming the landscape of mold manufacturing. By 2025, Repmold’s influence has become even more pronounced, setting new standards for quality, efficiency, and environmental responsibility.

Pioneering Technological Advancements

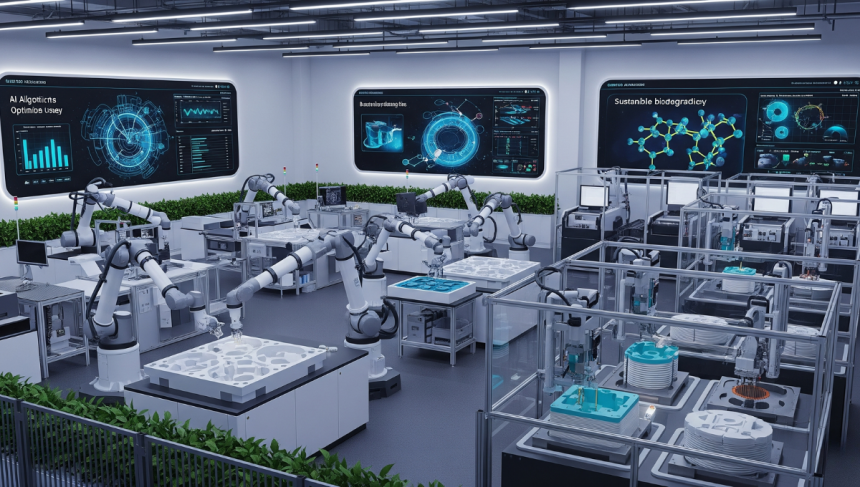

Repmold’s proactive embrace of emerging technologies has positioned it as a frontrunner in the mold manufacturing sector. In 2025, the company harnesses advanced automation, artificial intelligence, and 3D printing to streamline mold design and production processes. These innovations have drastically reduced lead times, minimized errors, and enhanced the precision of molds, allowing manufacturers to meet tight deadlines and complex specifications with confidence.

Sustainable Manufacturing Practices

A deep-rooted commitment to environmental sustainability forms the foundation of Repmold’s corporate ethos. By 2025, the company has implemented eco-friendly materials and energy-efficient manufacturing techniques. Recycling initiatives, waste reduction strategies, and the adoption of renewable energy sources have significantly lowered Repmold’s carbon footprint. Such practices not only benefit the planet but also resonate with clients seeking sustainable solutions, solidifying Repmold’s reputation as an industry leader committed to corporate responsibility.

Impact on Global Industries

Repmold’s innovations have had a ripple effect across various sectors, including automotive, consumer electronics, healthcare, and aerospace. The ability to produce highly precise and durable molds has enabled these industries to develop better products faster and more economically. For instance, in the automotive sector, Repmold’s molds contribute to the production of lightweight, high-performance parts that improve fuel efficiency and safety.

Driving Industry Standards and Collaboration

In 2025, Repmold’s influence extends beyond its own operations. The company actively collaborates with industry partners, research institutions, and technology providers to set new standards for mold manufacturing. These collaborations foster knowledge sharing and the development of next-generation materials and processes, ensuring that the industry as a whole advances toward greater innovation and sustainability.

Future Outlook

Looking ahead, Repmold’s trajectory suggests continued growth and innovation. Its focus on integrating smart technologies, reducing environmental impact, and fostering industry partnerships positions it as a key driver of progress in mold manufacturing. As the world moves toward smarter, greener, and more efficient production methods, Repmold’s role in shaping this future remains vital.

Conclusion

By 2025, Repmold has not only revolutionized mold manufacturing but also exemplified how innovation and sustainability can coexist to create a more efficient and responsible industry. Its advancements are setting the stage for a future where high-quality molds and environmentally conscious practices go hand in hand, inspiring the entire manufacturing ecosystem to evolve and thrive.